What are The Processing Technologies of Aluminum Alloy Shell?

2023-09-28 09:59The processing technology of aluminum alloy shell mainly includes the following:

Milling processing: Through milling machines, CNC machine tools and other equipment, the excess part of the surface of the aluminum alloy shell is removed to achieve the required shape and size.

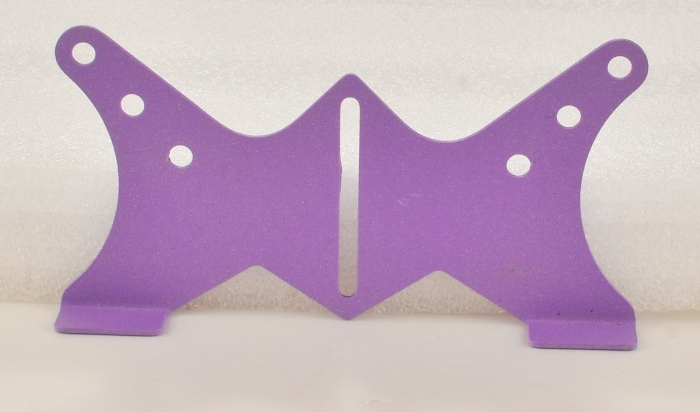

Drilling: Using tools such as drilling presses or drills to process holes in the aluminum alloy shell. It can be used to install bolts, latches and other connectors, or for ventilation and heat dissipation.

Stamping processing: Through the punching machine and other equipment, the use of molds to cut, bend, stretch and other processing of aluminum alloy sheet to create the required shell shape.

Bending processing: through the bending machine and other equipment, the aluminum alloy sheet is bent according to the required Angle and shape to achieve the three-dimensional structure of the shell.

Welding process: Using argon arc welding, resistance welding and other methods, the different parts or materials of the aluminum alloy shell are connected to increase the strength and tightness of the shell.

Surface treatment: including anodizing, spraying, electroplating and other processes, used to improve the corrosion resistance, appearance quality and surface hardness of the aluminum alloy shell.

These processing technologies can be combined according to specific requirements and different design requirements to meet the functional, aesthetic and performance requirements of aluminum alloy enclosures.