ABOUT US

Gao Yao District Jinli Town MEILIDU Hardware factory is a collection of R & D, production and sales as one of the professional manufacturers, the company's main wheel, doors and Windows accessories and plastic products. In order to users can use more perfect products, we quietly work, "quality casts trust" is our business philosophy.

Theory of business

Our development to doors and Windows hardware market with good quality, high taste of enjoyment, to meet the requirements of users. Close to the trend of The Times, "customer first", is our constant business philosophy. In line with the idea of innovation, we will create a personalized living space with good technology, and meet your needs with a variety of styles. The strength of the United States hardware to shape the brand, with the sincerity to win customers!

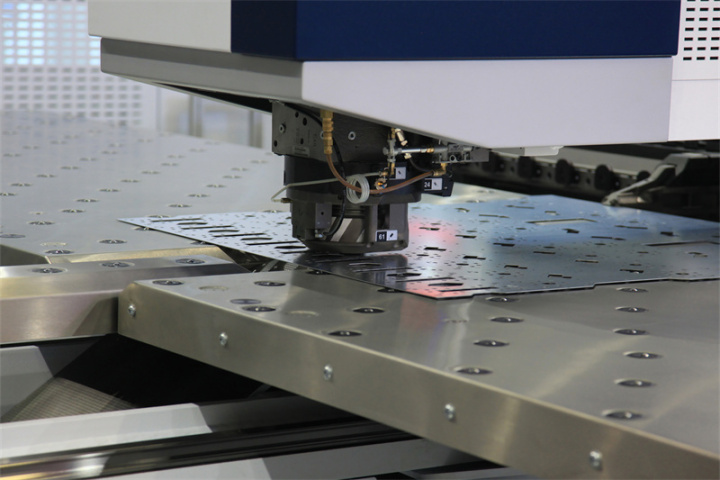

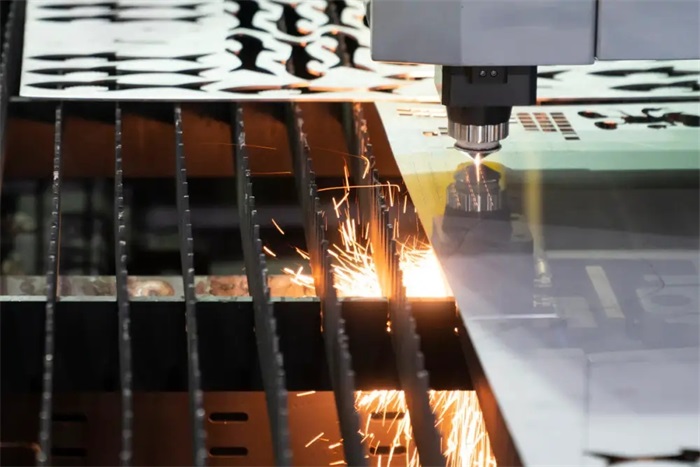

Mainly produce the stamping parts, sheet metal parts, mold making, spark-erosion wire cutting, CNC machining, laser cutting and welding. Our company own various equipments about 100, such as: Gantry milling, Laser cutting, Bending machine, Shearing machine, Punching machine 8T-200T, CNC Machining center, CNC Lathe machine, Milling machine, Wire-electrode cutting, Grinding machine, Drilling machine, Threading machine, Argon welder, Gas shielded welding machine, Spot welding machine, Squeeze riveter(Pressure riveting machine), Laser marking machine. Company has rich experience in mold design and excellent manufacturing capability, strict quality control system, for customers from product design, mould manufacture to the product production do unified service! And passed ISO9001: 2008 quality certification system and TS16949: 2009 certification system, our products are exported to Europe, America, Australia, Spain, Netherlands, Philippines, Italy, Japan and other countries, for many years deep old customer recognition, on the basis of mutual benefit common development, to provide stable and reliable quality service to our customers.

Main products are automotive stamping parts, exhaust pipes, sheet metal parts of rail transit equipment and motor machining products. It mainly produces sheet metal parts of subway doors, shielding doors and air conditioner; Automotive stamping parts for motor corporation; Lathing, machining, welding parts of motor; Industrial oven machine parts; Mechanical parts for elderly mobility vehicles and wheelchairs; Equipment accessories of garbage squeezing and fruit/vegetable machine; Machinery parts for printing presses.

Material:as Per Customer′s Requirement

Processing Method:Stamping parts, sheet metal parts, mold manufacturing, electric discharge wire cutting, CNC machining, laser cutting and welding, etc.

Technics: as Your Require

Process Combination: as Your Require

Manufacturing Technology: Computer Technology

Wide application range: medical equipment, new energy equipment, financial equipment, electronic equipment, 5G communication equipment, railway equipment, smart home equipment, military equipment.

Material of rice gold: cold rolled plate, hot rolled plate, galvanized plate, pickled plate, electrolytic plate, brass, red copper, copper, aluminum plate, hard aluminum, aluminum profile, stainless steel.

Application fields: communication, bridges, electricity, construction, industrial equipment, vehicle, ship transportation, household goods, public facilities, office supplies

Material of rice gold: cold rolled plate, hot rolled plate, galvanized plate, pickled plate, electrolytic plate, brass, red copper, copper, aluminum plate, hard aluminum, aluminum profile, stainless steel

Formed parts: automotive parts, engineering machinery parts, machine tool casings, cabinets, chassis, automotive casings, distribution cabinets

Processing steps: flanging, embedding flanging, bending, ribs, stamping, punching, grooving, cutting, rounding, forming, unfolding

Sometimes laser cutting as first processing to finish one job, but sometimes, it is not enough; we are pleasure to satisfy major customers’ requirements, now we can provide sheet metal bending services in same roofing. After cutting, the bending braking machine operated with our experience workers to produce all different of custom sheet metal parts.

Looking forward to your sincere cooperation!