How to Choose Sheet Metal Housing?

2023-10-02 09:10Sheet metal housing selection recommendations.

Choosing the right sheet metal shell needs to consider a number of factors, including use, environmental conditions, budget, and so on. Here are a few key points for choosing a sheet metal shell:

Material selection: Common sheet metal materials include steel, aluminum and stainless steel. The steel plate has high strength and rigidity and is suitable for scenarios requiring higher protective properties. Aluminum sheets are lightweight and corrosion-resistant for applications that require weight limitations or high appearance requirements. Stainless steel material has good corrosion resistance and high temperature resistance, suitable for harsh environments or special needs.

Thickness selection: According to the use of the environment and the required strength, choose the appropriate sheet metal thickness. Thicker sheet metal can provide higher structural strength and impact resistance, but adds weight and cost. Thinner sheet metal is lighter, but may sacrifice some protection.

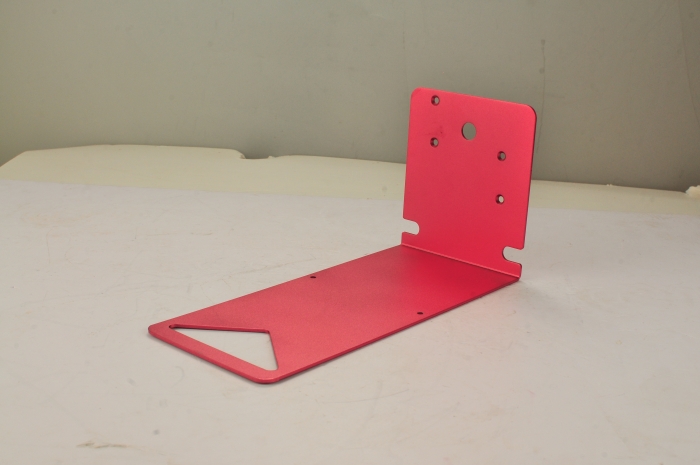

Surface treatment: Select the appropriate surface treatment according to the actual needs, such as spraying, electroplating, anodizing, etc. The surface treatment can not only increase the appearance of beauty, but also provide additional corrosion resistance, wear resistance and other characteristics.

Structural design: The structural design of the sheet metal shell should be reasonable to meet the functional requirements and assembly requirements. Taking into account maintainability and easy installation, the appropriate connection mode and inlet and outlet location are designed to facilitate future maintenance and repair.

Cost factor: Select the appropriate sheet metal housing according to budget constraints and cost-effectiveness. Different materials and processes will affect the price, considering the required performance and economy, to find a balance.

In summary, the selection of sheet metal shell needs to consider factors such as material, thickness, surface treatment, structural design and cost. In the selection process, professionals or sheet metal manufacturers can be consulted to evaluate and make decisions based on specific needs.